The Low Down on Large Chamber Gauges

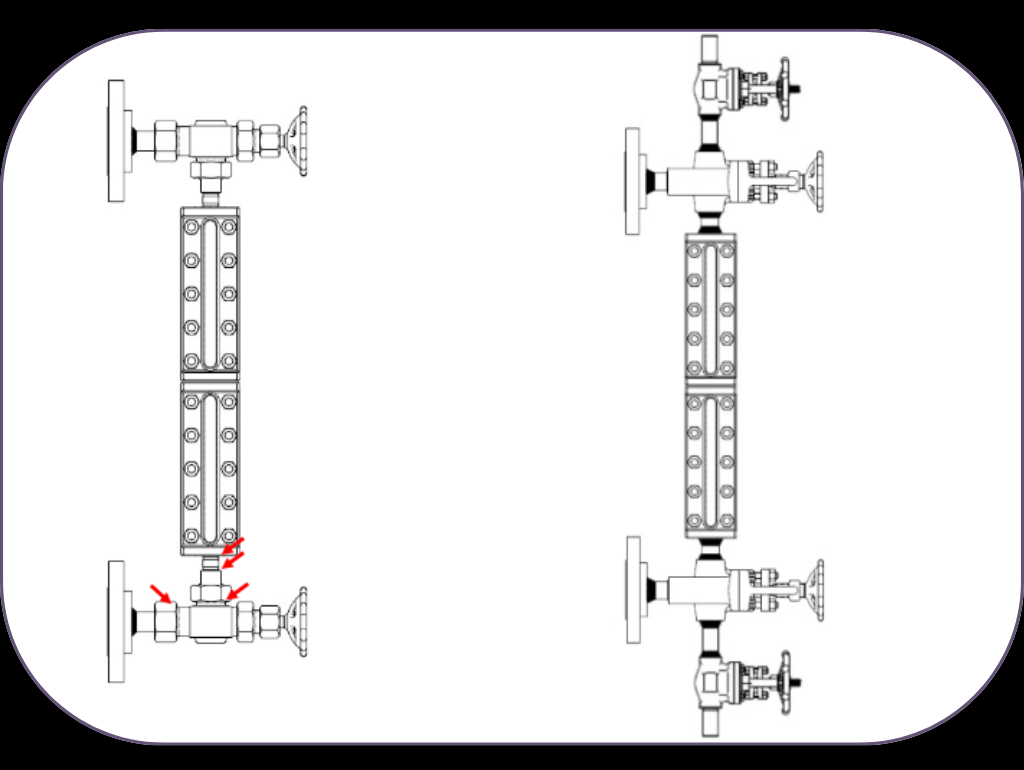

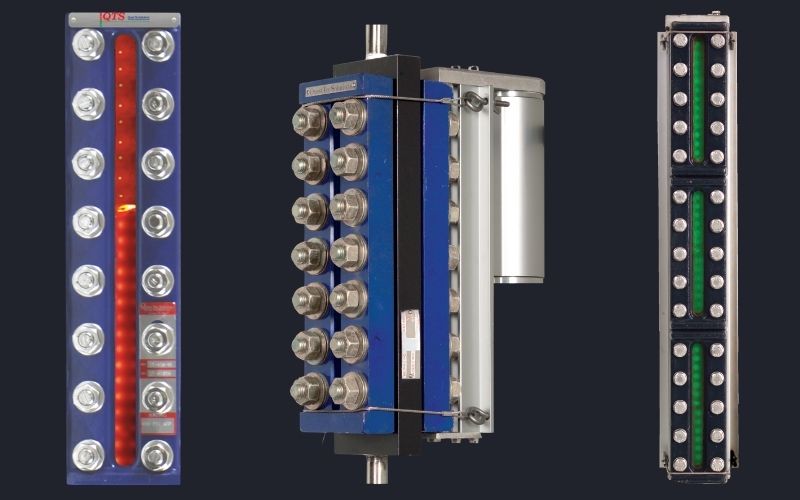

Glass-Trac Large Chamber Gauges are made in a special low-pressure series in both Reflex and Transparent Gauges. The large diameter chamber makes accurate liquid level readings possible under unusual conditions such as boiling, flashing, foaming, and interface stacking. Recessed seats are machined into the liquid chamber and gauge covers for protection of glass, gasket, and […]

The Low Down on Large Chamber Gauges Read More »