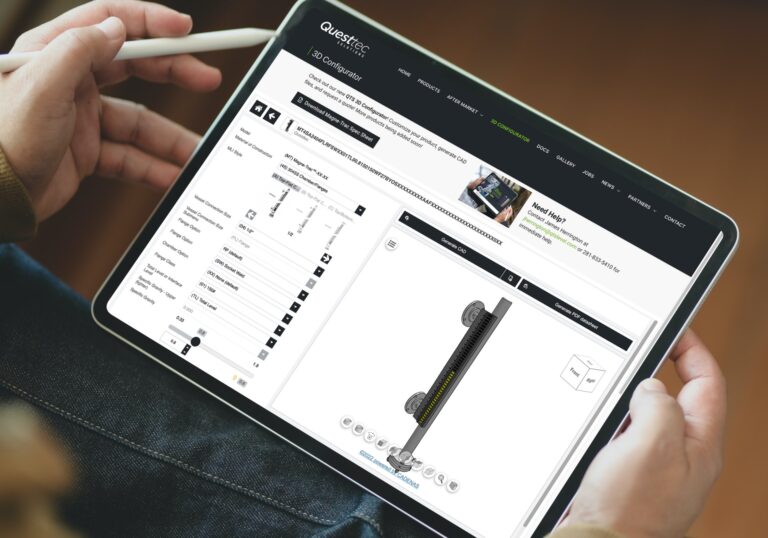

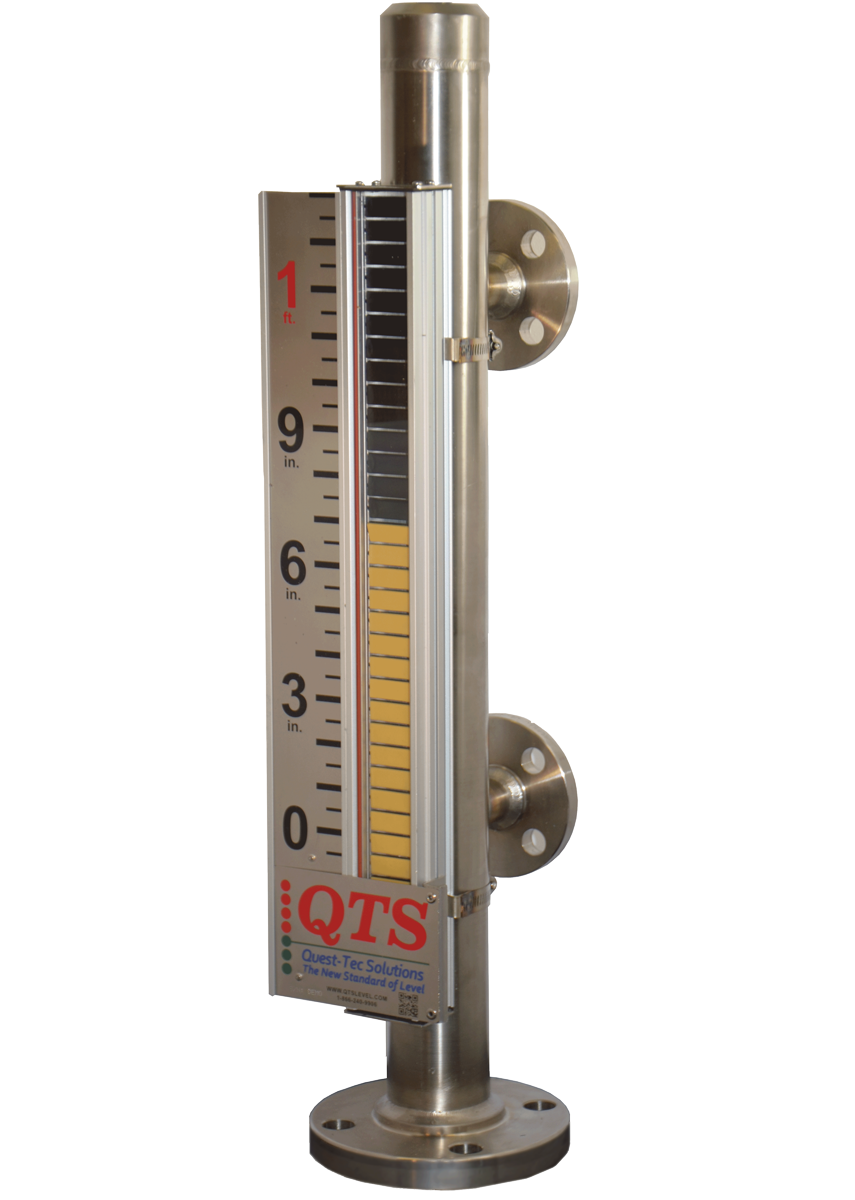

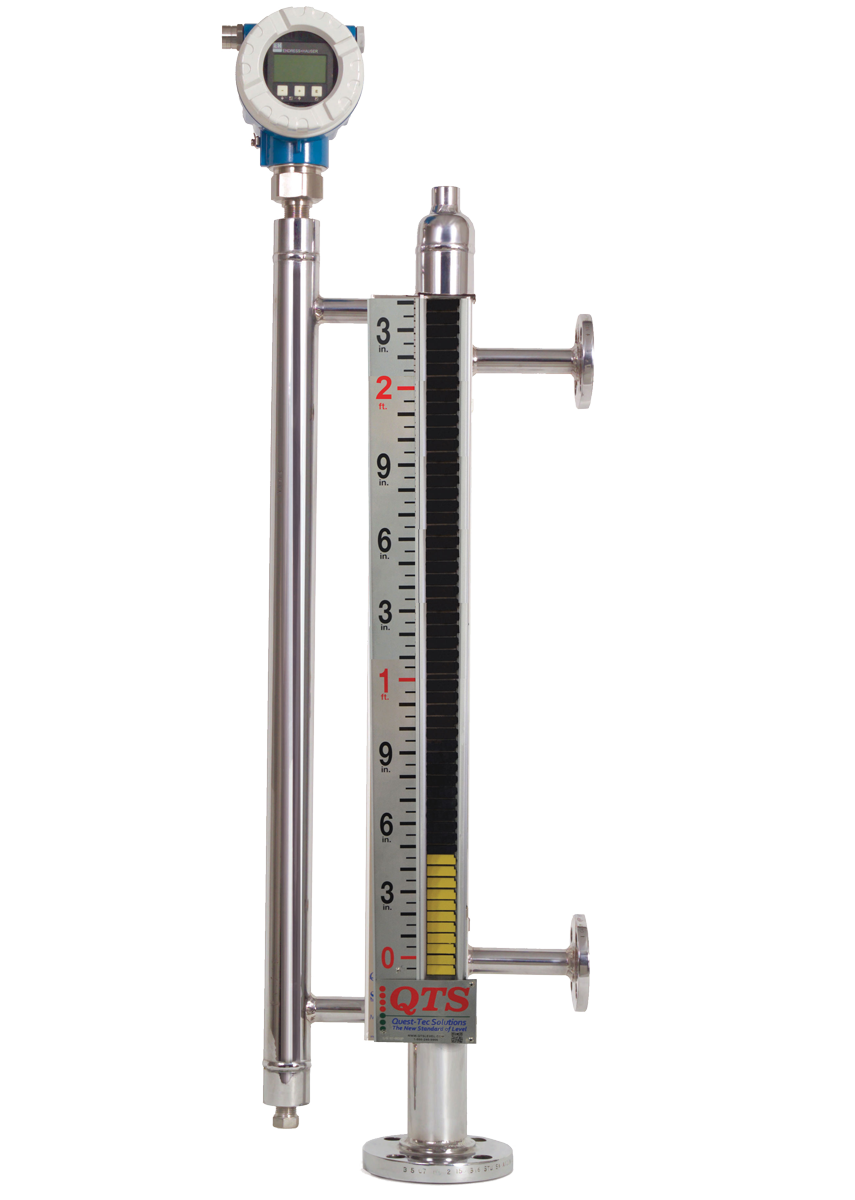

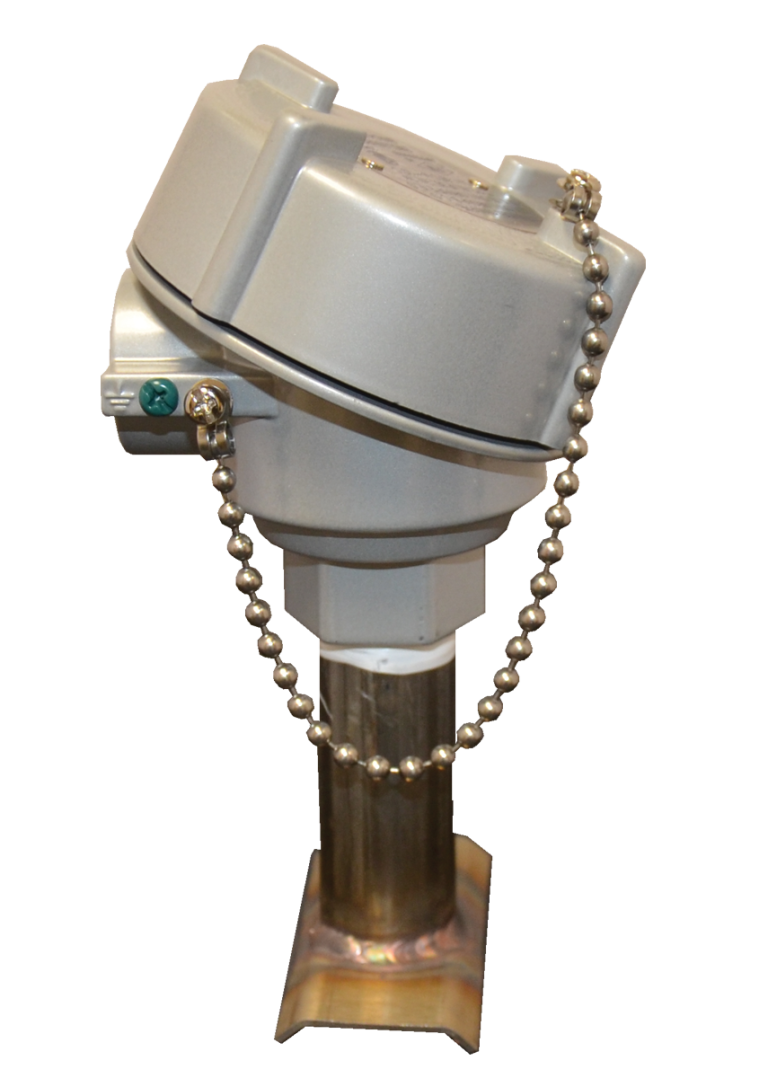

Magne-Trac Standard

Magnetic Level Indicator

- Innovative Flag Design Maximizes Magnetic Field

- Wide Flags for Enhanced Indicator View

- Impact Resistant Polycarbonate Indicator Window

- Corrosion Resistant Moving Parts

- Wide Variety of Materials

- Available to ASME 31.1/31.3 Standards