Accurate Liquid Level Readings with Glass-Trac Large Chamber Gauges

Unusual conditions, such as boiling, flashing, or foaming of the liquid, require an unusual product. Questtec Solutions’ Glass-Trac Large Chamber Gauge is the solution to unusual conditions.

Made in a special, low pressure series in both Reflex and Transparent Glass Gauges, the large diameter chamber makes accurate liquid level readings possible in unusual conditions.

Product Features

Manufactured from heavy duty, seamless steel pipe with an inside diameter of 2⅛ inches, each end of the pipe is closed off with a welded plug, which is drilled and tapped for ¾ inch NPT connections.

For close hook-ups, ¾ inch NPT side connections are made and the ends may be drilled, tapped, and/or plugged for cleaning as required.

Recessed seats are machined into the liquid chamber and gauge covers for protection of glass, gasket and cushion. Special bolts are used. Large Chamber Gauges are made in lengths for standard flat glasses and multiple section gauges are available.

Offset Gauge Valves Give Greater Flexibility

Questtec offers Offset Gauge Valves that extend the flexibility of our Large Chamber Gauges. The “offset” feature permits easy cleaning of gauges.

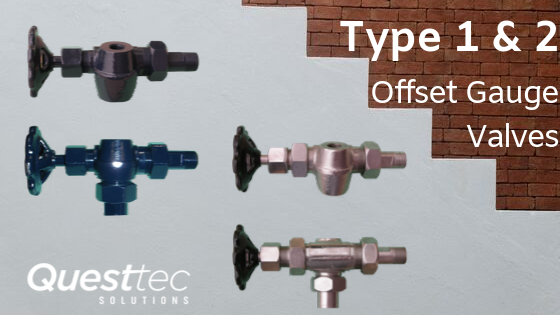

Type 1 & 2 Offset Gauge Valves

Type 1 and 2 Offset Gauge Valves are available with screwed (S), union (U), and tubular (T) gauge connections, and are used with Reflex and Transparent Gauges in working pressures up to 4000 psi and with Tubular Gauges to their maximum rating.

The Teflon packing ring is standard and used in services up to 450º F. For temperatures to 700º F, valves are fitted with special wire graphite packing.

Glass-Trac Type 1 Offset Gauge Valves have stainless steel ball checks to shut off the flow automatically in case of gauge glass breakage.

Glass-Trac Type 2 Offset Gauge Valves have an optional backseating stem allowing the packing to be changed without shutting down the vessel.

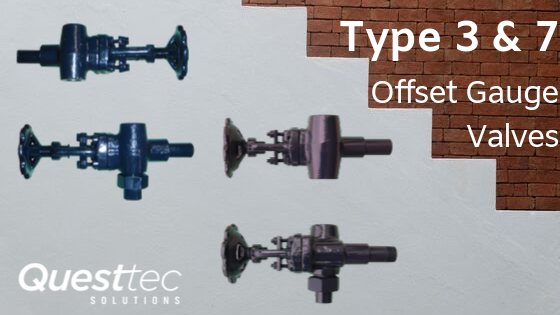

Type 3 & 7 Offset Gauge Valves

Type 3 and 7 Offset Gauge Valves are offered in both screwed (S) and a union (U) gauge. They have an Outside Screw & Yoke (OS&Y) design which prevents excessively hot and corrosive fluids from contracting stem threads, causing possible malfunction. The stem backs directly off the regrindable valve seat using the positive, non-rotating stem principle.

The Glass-Trac Type 3 Offset Gauge Valve can be supplied, on special order, in a tubular (T) gauge or other type of connection.

The Glass-Trac Type 7 Offset Gauge Valve has a backseating stem as a standard feature. Stainless steel ball checks are available upon request.

Straight-Thru Gauge Valves Offers Seamless Vessel Center Connections

The “straight-thru” valve body design is popularly used with close hook-up (side connection) gauges because the gauge side connection centers and vessel centers can be identical.

Type 4 and 5 Straight-Thru Gauge Valves are available with screwed (S) and Union (U) gauge connections and used with Reflex and Transparent Gauges in working pressures up to 4000 psi.

Valves are forged with carbon steel and stainless steel rims. A molded Teflon packing ring is standard at no extra cost in valves for services to 450ºF. For temperatures to 700º F, valves have wire-graphite packing.

The Glass-Trac Type 4 Straight-Thru Gauge Valve has a ¾” NPT Male Tank Connection as standard, with other connections available on order, as well as stainless steel ball checks to shut off the flow automatically in case of gauge glass breakage. An optional back seating stem is available upon request.

The Glass-Trac Type 5 Straight-Thru Gauge Valve has the Outside Screw & Yoke design which prevents excessively hot and corrosive fluids from contacting stem threads, causing possible malfunction. The valve has an optional bleed valve, which can be used in a block and bleed application. Stainless steel ball checks are available upon request.

About Questtec Solutions

Questtec Solutions is an international company with representatives based around the world. Our Partners can assist with commissioning start up and calibration, 24-hour service, and repair support.

Questtec Solutions employs over 125 years of collective experience with all aspects of liquid level gauge and valve product lines. With a new state-of-the-art manufacturing facility and custom weld shop based in Houston, Texas, Questtec Solutions is able to provide innovative engineered solutions to meet our customer’s specific needs.