11 Reasons Why Correct Level Measurement of Boiler Water Is Essential for Plant Safety and Compliance

by Jordan Bunting, Chief Technology Manager

Accurate boiler water level measurement is not only a regulatory requirement, it’s your primary defense against catastrophic failures that can destroy equipment, endanger lives, and shut down operations. From small industrial facilities to massive power generation plants, proper level monitoring prevents disasters while ensuring regulatory compliance and operational efficiency. This is why modern industrial facilities depend on precision level instrumentation to maintain safe, efficient, and compliant boiler operations.

Here are the 11 critical reasons why investing in accurate level measurement technology is a non-negotiable for any facility operating steam boilers.

1. Prevents Catastrophic Boiler Explosions

Boiler explosions can be one of the most devastating industrial accidents. They’re capable of destroying entire facilities and even causing injury or fatalities. When water levels drop below critical thresholds, exposed heating surfaces can reach extreme temperatures exceeding 1600°F, creating conditions for violent pressure vessel failure.

When water circulation is interrupted by low levels, “thin-lipped” bursts occur due to plastic flow conditions in overheated metal. These explosive failures happen rapidly—often within minutes of losing adequate water coverage over heated surfaces.

The consequences can be severe. Thus, accurate level measurement provides the critical early warning needed to prevent these catastrophic events through automatic shutdown systems and operator alerts.

2. Ensures ASME Section I Code Compliance

ASME Section I mandates specific water level instrumentation requirements for all steam boilers, with strict penalties for non-compliance. In fact, facilities operating without proper level measurement face regulatory shutdowns, hefty fines, and insurance claim denials.

Key compliance requirements include:

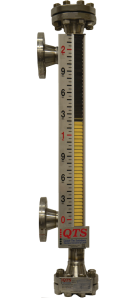

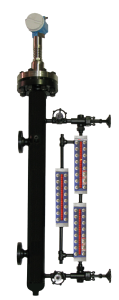

- All boilers must have at least one gage glass for visual level indication

- Boilers above 400 PSI require two gage glasses or approved remote level indicators

- Level instrumentation must meet precise positioning and materials specifications

- Regular testing and maintenance documentation is mandatory

(You can read more about these design and code rules in our article 11 Magnetic Level Indicator Design & Code Rules for ASME Section I Boilers.)

Financial impact: Non-compliance can come with negative financial impacts, such as immediate facility shutdown orders, fines exceeding $100,000, and invalidated insurance policies that leave companies exposed to massive liability claims.

3. Protects Against Tube Overheating and Failure

Tube failures from overheating represent the most common and expensive boiler maintenance issue, with replacement costs often exceeding $500,000 per incident. When water levels drop, waterwall tubes lose their cooling protection and rapidly overheat.

Low water conditions cause “snaking” of waterwall tubes, leading to furnace wall projections and instant “fish mouth” tube failures that can trigger secondary explosions. The overheating damage typically affects multiple tubes simultaneously, requiring extensive furnace reconstruction.

Prevention value: Proper level measurement prevents tube replacement costs, eliminates weeks of unplanned downtime, and maintains heat transfer efficiency. In fact, a single prevented tube failure incident typically pays for advanced level measurement systems multiple times over.

4. Maintains Optimal Steam Quality

Water level directly impacts steam purity and quality, which is an essential factor for process industries and power generation. Excessive water levels can cause carryover of boiler water solids into steam lines. In addition, low levels can create dry conditions that affect steam temperature control.

Process impacts include:

- Contaminated steam damages downstream equipment like turbines and process heat exchangers

- Poor steam quality reduces heat transfer efficiency in manufacturing processes

- Variable steam conditions create product quality issues in industries requiring precise temperature control

Accurate level control maintains the optimal steam-water interface, ensuring consistent, high-quality steam output that meets process requirements and protects expensive downstream equipment.

5. Prevents Expensive Equipment Damage

Beyond the boiler itself, incorrect water levels can threaten entire steam systems. Low water conditions create overheated components that crack and warp. And the sudden addition of cold water to overheated surfaces can generate explosive steam formation.

Equipment at risk includes:

- Superheaters that can’t tolerate dry conditions or water slugs

- Steam turbines vulnerable to water carryover damage

- Heat exchangers and process equipment requiring clean steam

- Pumps and piping systems subject to thermal shock

Cost considerations: Replacing a damaged steam turbine can cost millions of dollars and require months of downtime. Proper level measurement protects these critical assets while maintaining system reliability.

6. Enables Proper Feedwater Control

Modern boiler control systems depend entirely on accurate level measurement for automated feedwater control. Failed water level controls prevent the feed pump from maintaining adequate water supply, leading to dangerous low-water conditions.

Control system benefits:

- Automatic water level regulation reduces operator workload

- Precise level control optimizes boiler efficiency and fuel consumption

- Integrated safety systems provide multiple layers of protection

- Remote monitoring capabilities enable 24/7 supervision

Without reliable level measurement, operators must resort to manual control methods, which can increase human error risks and reduce operational efficiency.

7. Reduces Insurance Premiums and Liability

Insurance companies require specific safety instrumentation, including redundant level measurement systems, to provide coverage for boiler operations. Facilities with inadequate level monitoring face higher premiums, coverage exclusions, and potential claim denials.

Insurance considerations:

- Comprehensive level measurement systems demonstrate risk management commitment

- Regular maintenance records and testing documentation support coverage

- Advanced safety systems often qualify for premium discounts

- Claims involving inadequate safety systems face intense scrutiny and potential denial

Legal protection: Proper level measurement provides crucial evidence of safety compliance in litigation, protecting companies from negligence claims and regulatory penalties.

8. Ensures Operator Safety

Boiler incidents primarily occur due to catastrophic failures during low water conditions, creating immediate danger to plant personnel. Accurate level measurement with automatic shutdown capabilities protects workers from steam releases, explosions, and thermal exposure.

Safety features include:

- Automatic boiler shutdown before dangerous conditions develop

- Remote level monitoring reduces operator exposure to hazardous areas

- Clear visual and audible alarms provide immediate hazard notification

- Emergency response protocols based on level measurement data

Worker protection: Beyond preventing accidents, proper level measurement reduces stress and liability for operators responsible for boiler safety, creating a safer, more confident work environment.

9. Maintains Plant Efficiency and Performance

Optimal boiler efficiency requires maintaining precise water levels for proper heat transfer and steam generation. Incorrect levels reduce efficiency, increase fuel consumption, and decrease overall plant performance.

Efficiency impacts:

- Proper water levels maximize heat transfer surface utilization

- Consistent steam output reduces energy waste and fuel costs

- Optimal level control minimizes cycling losses and startup energy

- Improved efficiency reduces environmental emissions and operating costs

Performance optimization: Advanced level measurement systems enable fine-tuning of boiler operations, achieving efficiency improvements of 2-5% that translate to significant annual fuel savings.

10. Prevents Costly Unplanned Downtime

Boiler failures from poor level control cause extended shutdowns for emergency repairs, replacement parts, and safety inspections. Unplanned downtime costs can be in the tens of thousands of dollars for industrial facilities and can reach millions for power plants.

Downtime prevention benefits:

- Predictive maintenance based on level trending prevents emergency failures

- Automatic protection systems avoid damage requiring extensive repairs

- Reliable operation maintains production schedules and customer commitments

- Planned maintenance windows reduce overall downtime compared to emergency repairs

Business continuity: Proper level measurement ensures reliable boiler operation, supporting consistent production and avoiding the cascading effects of unplanned shutdowns throughout facility operations.

11. Meets Environmental Compliance Standards

Modern environmental regulations require precise control of steam releases and water discharge from boiler operations. Accurate level measurement helps facilities meet stringent environmental standards while supporting sustainability goals.

Environmental benefits:

- Reduced steam venting through proper level control

- Optimized water treatment and blowdown operations

- Improved fuel efficiency reduces greenhouse gas emissions

- Proper level management minimizes waste heat and water consumption

Regulatory compliance: Environmental agencies increasingly scrutinize industrial steam operations. Comprehensive level measurement systems demonstrate environmental stewardship and help avoid costly violations or permit restrictions.

The Safe Investment Decision

Accurate boiler water level measurement represents far more than regulatory compliance. It’s essential infrastructure that protects lives, equipment, and business operations. The cost of advanced level measurement systems pales in comparison to a single avoided incident.

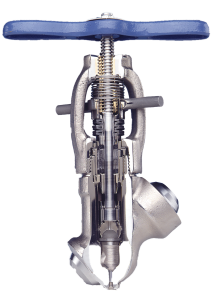

Modern facilities require:

- Redundant level measurement systems for critical applications

- Integration with plant control and safety systems

- Regular calibration and maintenance programs

- Operator training on proper level management procedures

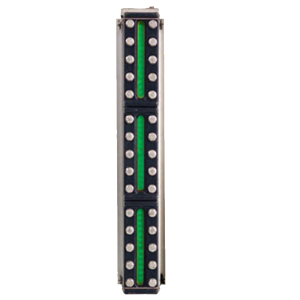

At Questtec Solutions, we understand that reliable level measurement forms the foundation of safe boiler operations. Our magnetic level indicators and comprehensive measurement solutions help facilities achieve the precision, reliability, and compliance required for modern industrial operations. Contact our engineering team to discuss how proper level measurement can protect your facility and ensure operational excellence.