Case Study: BioMass Cogeneration Plant

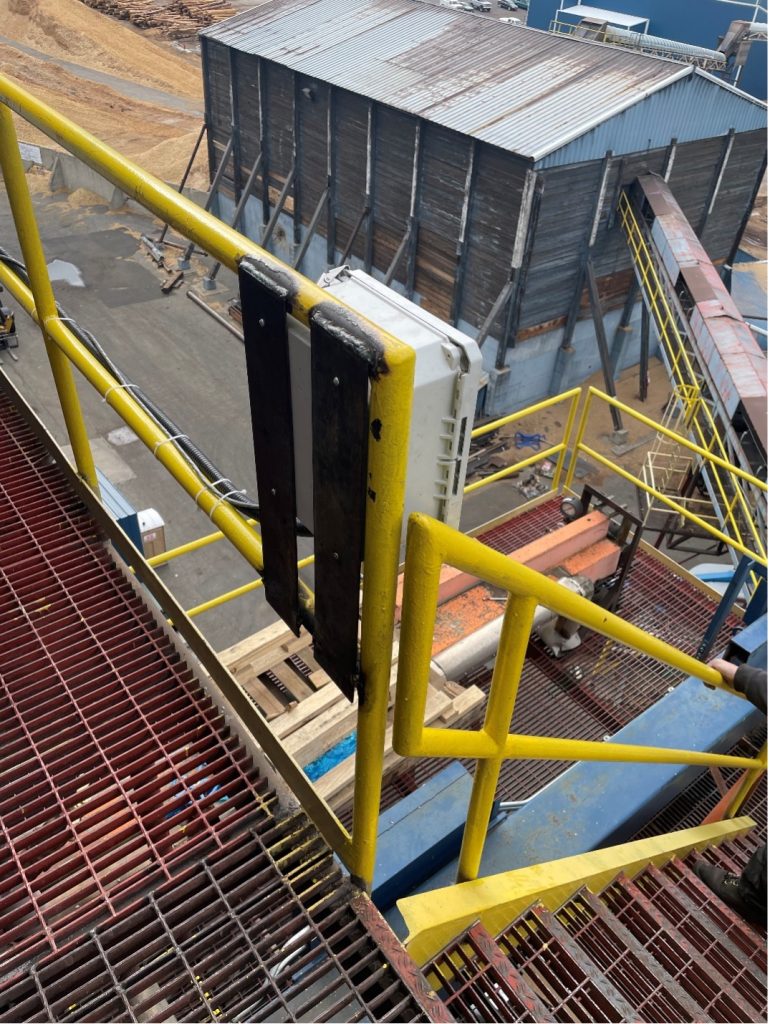

Recently, Questtec Solutions was asked to provide two sight glasses, a remote level monitoring solution, and boiler trip protection for a sawmill. This plant uses the wood chips from production to fire a boiler drum, providing steam to power the sawmill on site and sell remaining MW production to the grid.

These types of plants have the traditional “power plant level” opportunities on the following vessels:

- Boiler Drum

- Largest opportunity with both level monitoring and control applications and a stringent boiler code to adhere too. All potential opportunities include:

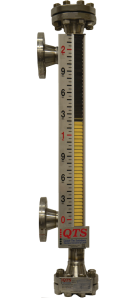

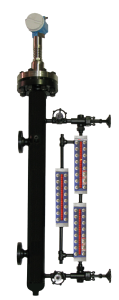

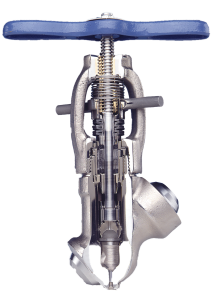

- Direct reading sight glass

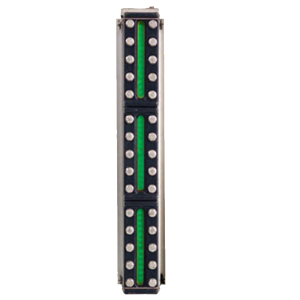

- Probe Column and/or GWR w/ control unit for trip protection/remote monitoring

- GWR or D/P for boiler level control

- The older method consisted of utilizing D/P transmitters for the level input for control

- The modern approach is to utilize the newer and more accurate GWR in an externally mounted GWR as opposed to D/P

- Largest opportunity with both level monitoring and control applications and a stringent boiler code to adhere too. All potential opportunities include:

- DA tank

- Condensers

Challenges

- Must adhere to ASME B31.1 Power Piping and ASME Section 1, PG-60 Boiler Code

- Small confined boiler house with minimal space for externally mounted equipment

- Limited process connections to boiler drum

- Customer wanted to lower maintenance frequency with more robust sight glass

- Sight glass was to be monitored by a camera for operators to view in control room. Needed to be illuminated and visible both day and night.

Solution