Is Your Glass Counterfeit?

Is the glass in your gauge not performing to spec? It could be counterfeit glass!

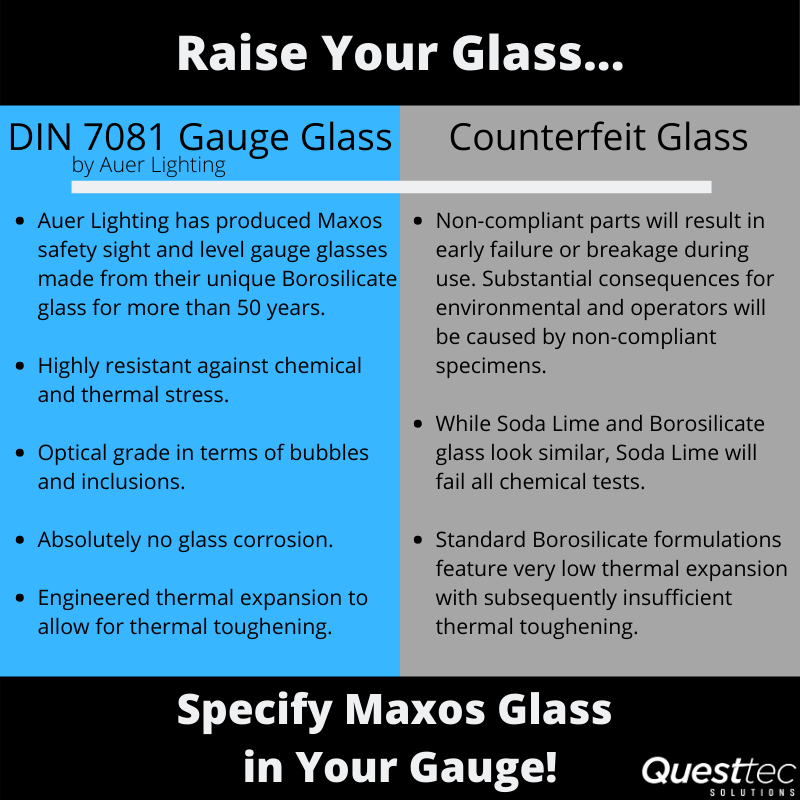

Soda lime and Borosilicate glass look very similar, but perform completely differently. Lately, there has been a rash of counterfeit glass introduced into the glass-gauge industry, some so-called companies even illegally using the corporate names of legitimate glass providers.

Questtec Solutions uses Auer Lighting, manufacturer of Maxos® glass, in our products to ensure safety and superior performance. Auer has made us aware of counterfeit manufacturers using their name to misrepresent non-performing products. If you have questions about your products, give us a call!

Why Auer MAXOS® Glass?

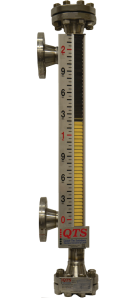

Our customers are economically more successful than others due to the outstanding material properties of SUPRAX® 8488 borosilicate glass.

MAXOS® Safety Sight and Level Gauge Glasses have earned themselves a reputation in the industry for highest production quality and unmatched material composition.

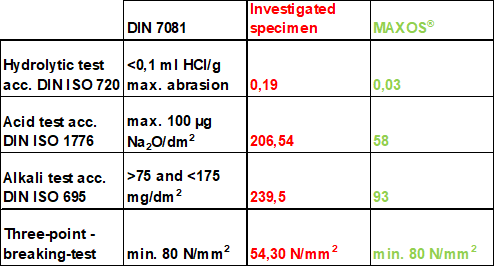

Auer products are subject to very rigid standards. Both glass composition and thermal toughening are analyzed and reviewed on regular basis by independent labs.

When verifying potential counterfeits, test results prove why MAXOS® glasses are superior for your application.

Auer Lighting – Superior Borosilicate Glass

Auer Lighting has produced Maxos® safety sight and level gauge glasses made from their unique Borosilicate glass for more than 50 years.

Their SUPRAX® 8488 Borosilicate glass is/has:

- Highly resistant against chemical and thermal stress.

- Optical grade in terms of bubbles and inclusions.

- Absolutely no glass corrosion.

- Engineered thermal expansion to allow for thermal toughening.

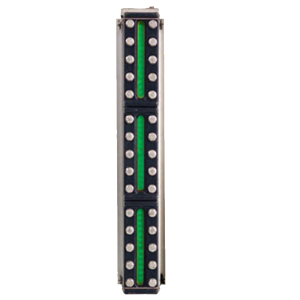

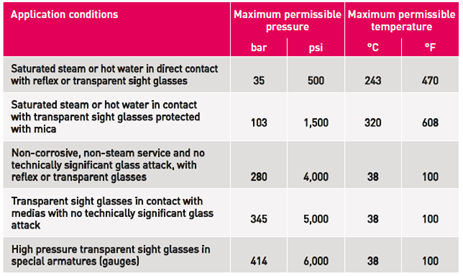

The Maxos® product range has specially tempered reflex and transparent level gauge glasses and disc sight glasses that can be supplied in accordance to:

- DIN 7080/7081

- MIL-G 16356 D

- High-Pressure

- Customer Specifications

Identifying Counterfeit Soda Lime Glass

One of the first steps to identifying counterfeit glass is to check and compare the paperwork, packaging, and most importantly, the toughening number on the product.

If you are unsure about documentation, give your Channel Partner a call. Auer will check production records against the dimension and toughening numbers.

In case doubts persist, Auer provides, free of charge, an independent laboratory contractor to do a full chemical analysis of the product.

Risks of Soda Lime Counterfeit Glass

Non-compliant parts will result in early failure or breakage during use. Substantial consequences for operators, personnel, and the surrounding environment will eventually be caused by non-compliant products.

While Soda Lime and Borosilicate glass look similar, Soda Lime will fail all chemical tests.

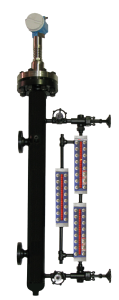

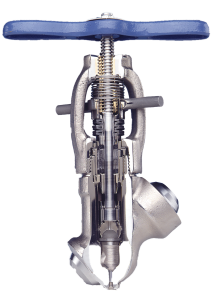

About Questtec Solutions

Questtec Solutions is an international company with representatives based around the world. Our Partners can assist with commissioning start up and calibration, 24-hour service, and repair support.

Questtec Solutions employs over 125 years of collective experience with all aspects of liquid level gauge and valve product lines. With a new state-of-the-art manufacturing facility and custom weld shop based in Houston, Texas, Questtec Solutions is able to provide innovative engineered solutions to meet our customer’s specific needs.