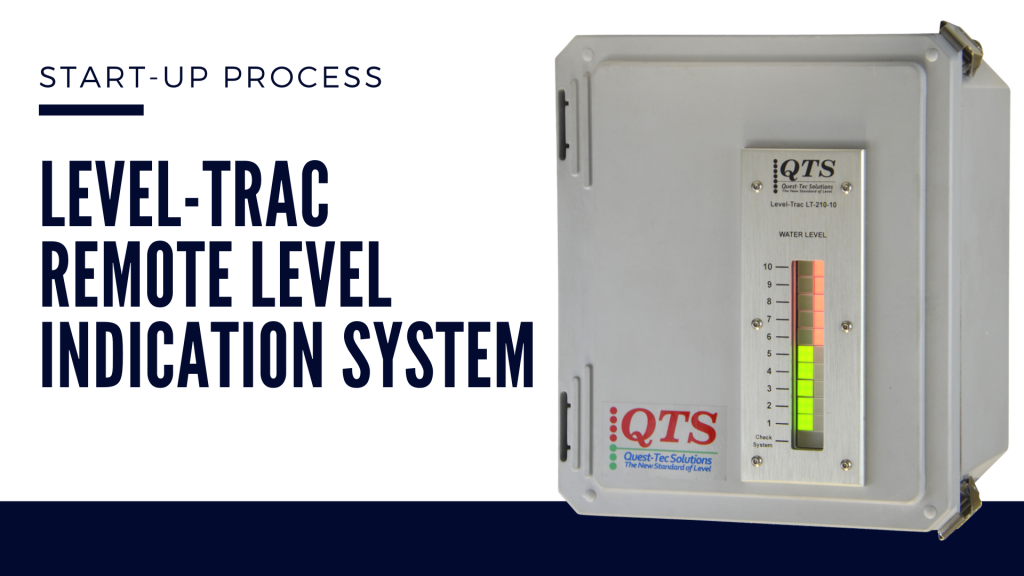

Level-Trac Start-Up Process

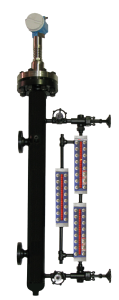

Built to last, Level-Trac manifolds feature robust construction to perform in the rigorous environment adjacent to steam generation equipment.

This post walks through how to prepare and start-up the Questtec Solutions’s Level-Trac Remote Level Indication system.

Before you begin, make sure you have the wiring diagram for the control unit, and diagram for remote display, if used. Each unit has a serial number, and the wiring diagram is marked accordingly. If the wiring diagram cannot be located, contact the factory with the serial number reference.

Level-Trac Remote Level Indication System Start-Up

Step 1

Start by routing the wire bundle into the control unit.

Step 2

Land each probe wire to its respective terminal on the plug PL1 and PL2. Pause and do not connect the plug. Double-check the wiring to the diagram.

Step 3

If used, land each remote display wire to its respective terminal on the “REMOTE DISPLAY” plug. Pause and do not connect the plug. Double-check the wiring to the diagram.

Step 4

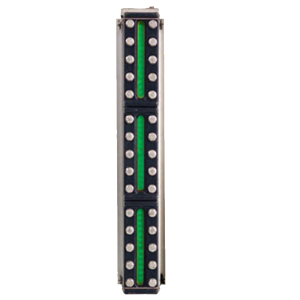

Prior to initially powering up, verify that the ribbon cable connecting the two PCBs is oriented correctly and fully seated. The red conductor must be towards the “1” marked on the PCB.

Step 5

Verify the power is off and install the wired probe plugs. Power up the unit, and observe; if the column is empty all probe channels should have the red LEDs illuminated.

Step 6

Turn off the power and install the wired remote display plugs, if used. To prevent permanent damage to the discriminator PCB, confirm that the wiring to the indicator is correct before powering up.

Step 7

Power up the unit and check the correct illumination of LED’s by operation of the green and red test buttons.

Step 8

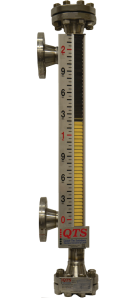

Bring the probe manifold online. Refer to the factory IOM.

Step 9

Compare the Level-Trac water level to other instrumentation and/or sight glass. Bear in mind that slight differences are to be expected.

If you have any questions, contact your Channel Partner to order your engineered solutions, designed with care by Questtec Solutions.

About Questtec Solutions

Questtec Solutions is an international company with representatives based around the world. Our Partners can assist with commissioning start up and calibration, 24-hour service, and repair support.

Questtec Solutions employs over 125 years of collective experience with all aspects of liquid level gauge and valve product lines. With a new state-of-the-art manufacturing facility and custom weld shop based in Houston, Texas, Questtec Solutions is able to provide innovative engineered solutions to meet our customer’s specific needs.