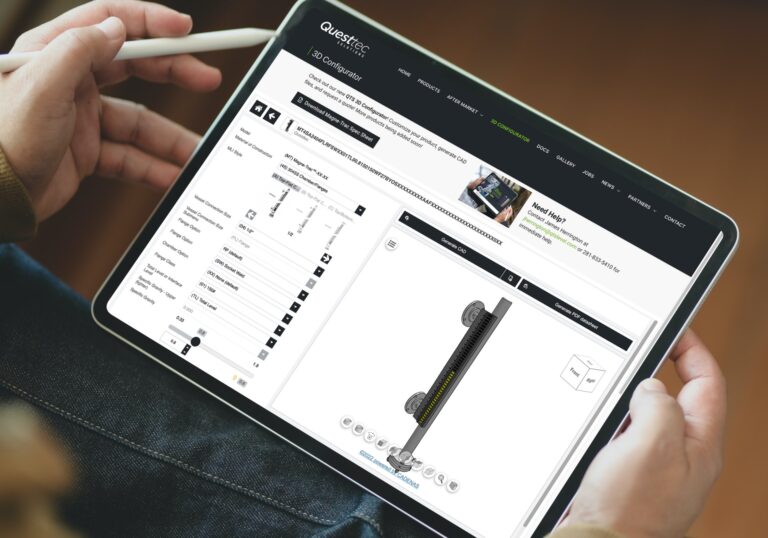

The new Magne-Trac 3D Configurator helps engineers quickly find a product and configure it on-the-fly to match their project specifications. Generate a product number and 3D preview of the configured part so you can see the exact part specified. Download a free 3D model in your preferred native CAD format, choosing from 150+ 3D and 2D CAD formats to test in your application.

Magne-Trac products are among the safest and most economical ways to measure liquid levels, excelling in applications of extreme pressure, temperature, vibration, and corrosive or hazardous materials.

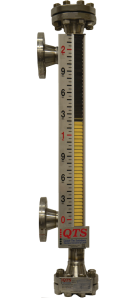

Disco-Trac

Magnetic Level Indicator

Questtec has partnered with leading GWR companies to provide customers selection flexibility based on specific application needs. GWR is preferred in the industry for its easy setup, reliable operation, measurement accuracy, and resistance to changing process conditions.

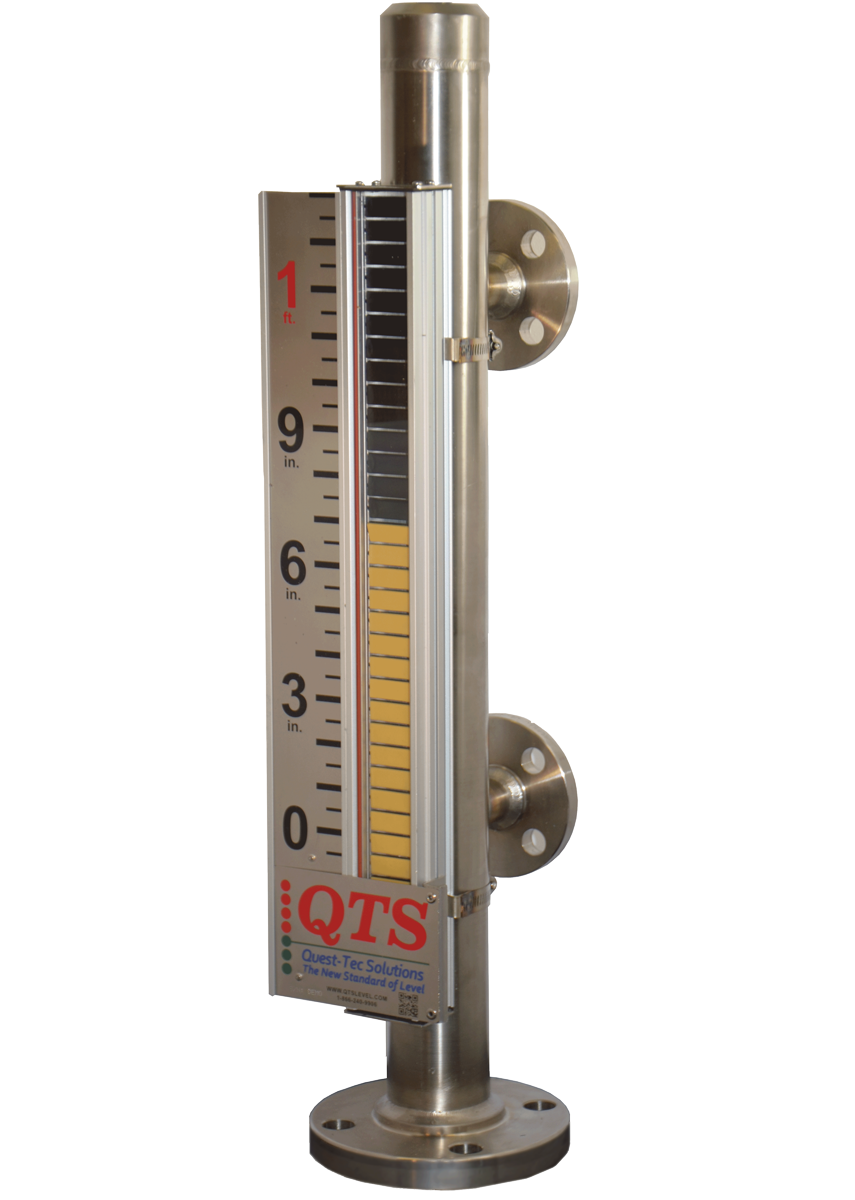

Magne-Trac Standard

Magnetic Level Indicator

- Innovative Flag Design Maximizes Magnetic Field

- Wide Flags for Enhanced Indicator View

- Impact Resistant Polycarbonate Indicator Window

- Corrosion Resistant Moving Parts

- Wide Variety of Materials

- Available to ASME 31.1/31.3 Standards

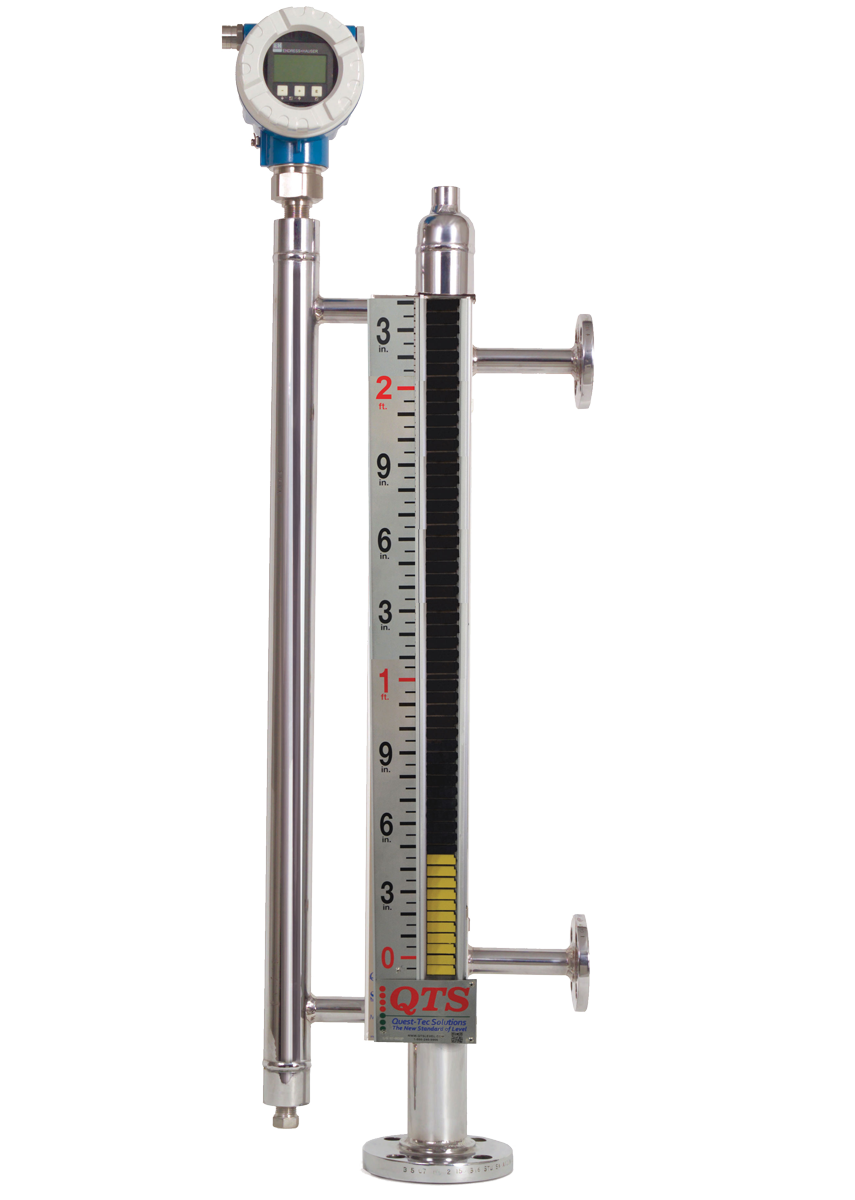

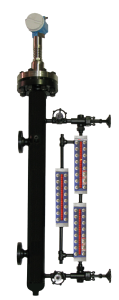

Magne-Trac Plus

Magnetic Level Indicator + Bridle Chamber

- Innovative Flag Design Maximizes Magnetic Field

- Wide Flags for Enhanced Indicator View

- Impact Resistant Polycarbonate Indicator Window

- Corrosion Resistant Moving Parts

- Wide Variety of Materials

- Available to ASME 31.1/31.3 Standards

Eco-Trac

Low Pressure and Temperature Magnetic Level Indicator

- Rated per ASME Class 150

- Standard Sch. 40 Pipe Chamber Construction

- Wide Flag Indicator for optimal viewing

- Low Pressure and low temperature option

MTLT-5000

Level Transmitter

- Designed to mount externally to the Magne-Trac

- No maintenance required

- Multidrop HART Communications

- FM Approved Explosion Proof/IS

- NEMA 4X/7 enclosure

- Modular design

- Adjustable output damping

- Up to .001” resolution

- 2-wire loop powered

- RFI/EMI protection

- Offers a 4/20 mA 2-wire loop powered circuit for continuous level measurement

- Available in lengths up to 300 inches

- Process temperature range: -30 to 400 degrees F.

- The Non-Contact design ensures no wear to the sensing element, thus requiring no maintenance or recalibration

MTLT-6000 Magnetostrictive

Quest-Tec Solutions Magnetostrictive Transmitters For Magne-Trac Gauges

- Modular design

- High accuracy and repeatability

- Multi-drop HART communication

- Explosion-proof and / or intrinsically safe (model dependent)

- No maintenance required

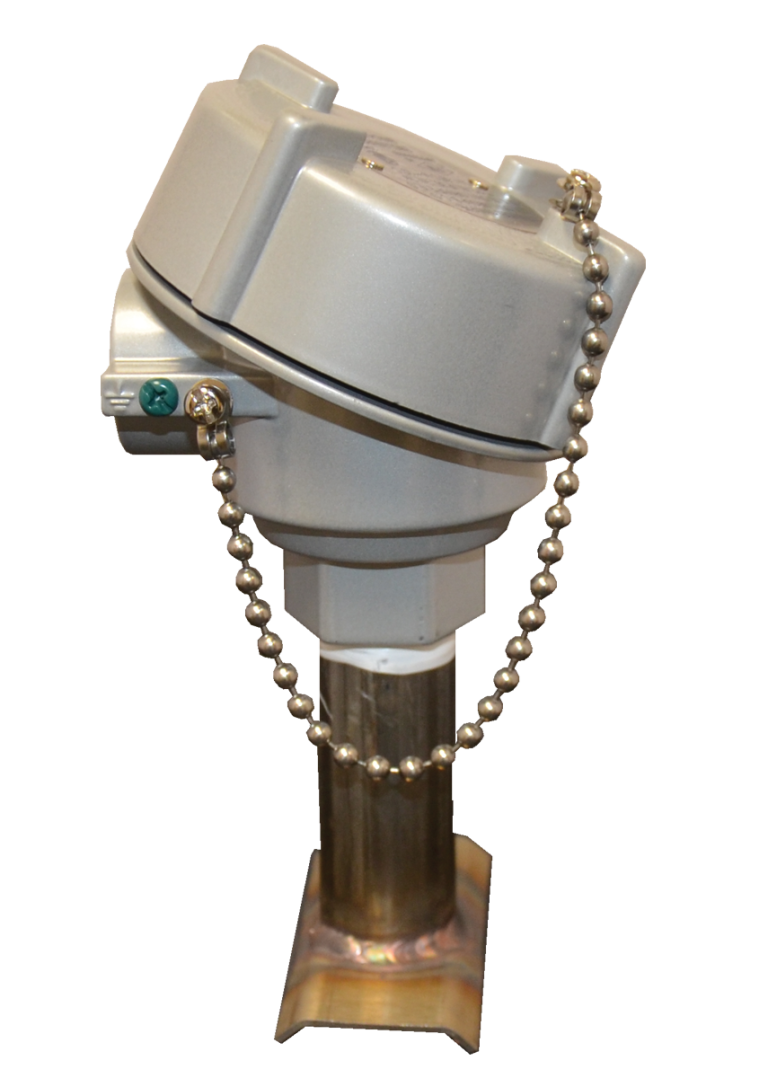

Maverick In-Tank Transmitter

Direct Insert Transmitter

- No maintenance required

- Multidrop HART Communications

- FM Approved Explosion Proof/IS

- NEMA 4x/7 enclosures

- Modular design

- Adjustable output damping

- Up to .001” resolution

- 2-wire loop powered

- RFI/EMI protection

- Offers a 4/20 mA 2-wire loop powered circuit for continuous level measurement

- Available up to 866 inches

- Process temperature range: -30 to 400°F

MTLS-1A

Level Switch

- Attached directly to chamber. Easily adjustable with clamps – no additional piping required

- Low cost alarm solution

- Single Pole Double Throw (SPDT) Switch

- Minimum Temperature Rating -40°F

- Enclosure Classifications Class 1 Div1; Groups B, C,D

MTLS-5A

Level Switch

- Attached directly to chamber. Easily adjustable with clamps – no additional piping required

- Low cost alarm solution

- Single Pole Double Throw (SPDT) Switch

- Minimum Temperature Rating -40°F

- Enclosure Classifications Class 1 Div1; Groups B, C,D

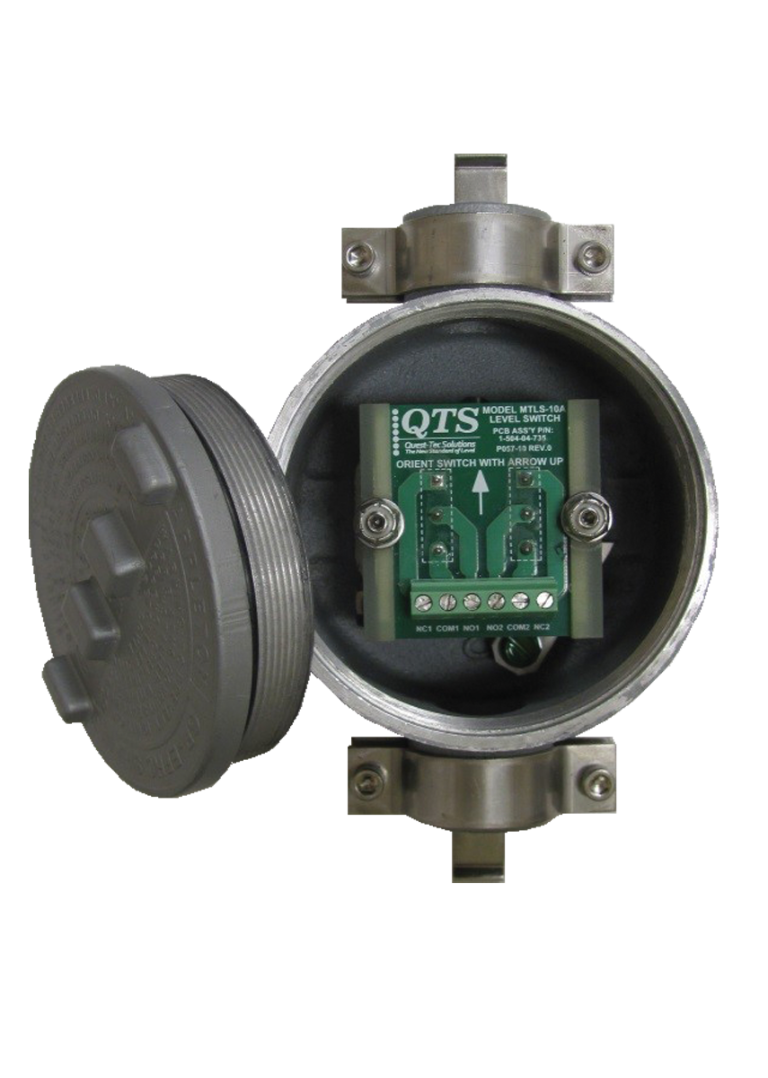

MTLS-10A

Level Switch

- Suitable for high / low level sensing

- Directly coupled with float magnetically – no direct connection with process fluid

- Latching, bi-stable design. Switch maintains state until return float passage in opposite direction

- Double Pole Double Throw configuration

- Attached directly to chamber. Easily adjustable with clamps – no additional piping required

- Minimum Temperature Rating -40°F

- Enclosure Classification Class 1 Div1; Groups B, C, D

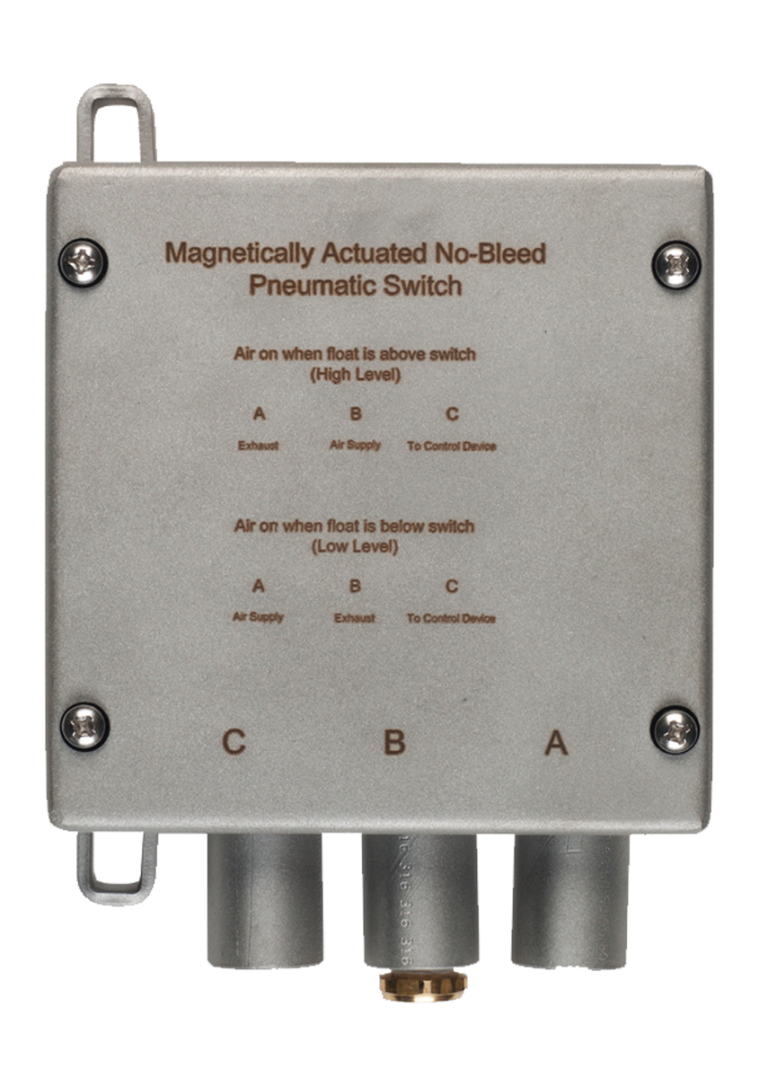

MTLS-PNEU

Non-bleed Pneumatic Switch

- Attached directly to chamber. Easily adjustable with clamps – no additional piping required

- Integral high volume, rapid response relay

- Magnetic Coupling design concept – no direct connection with process fluid

- Non-Corrosive housing

- Vibration resistant

- NEMA 4, stainless steel enclosure