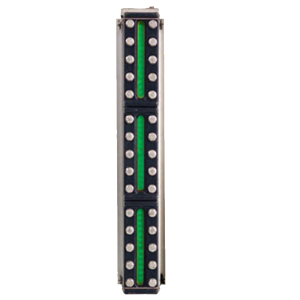

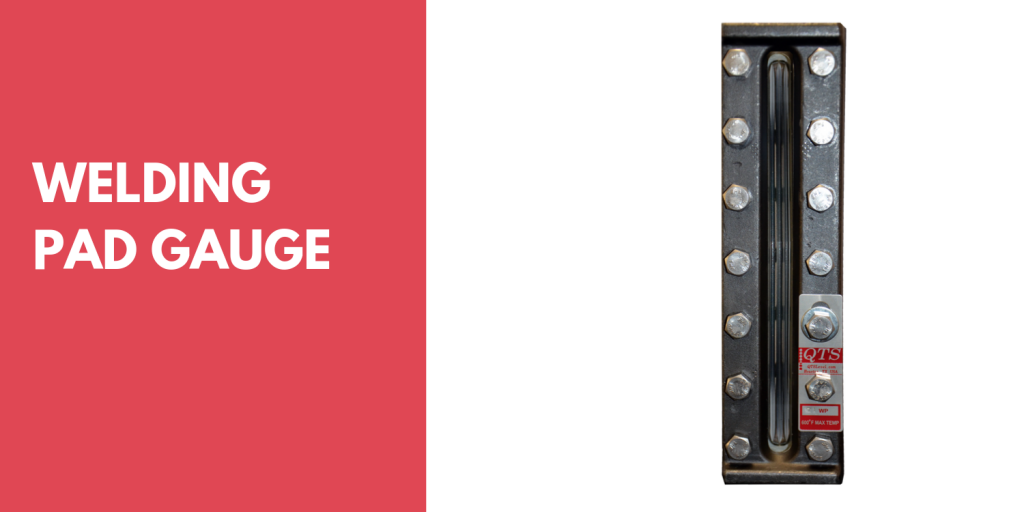

Specialty Gauges with Glass-Trac Welding Pads

When liquid products have solids in suspension, standard tank connections cannot be used. Questtec’s Glass-Trac Welding Pad Gauge is the solution.

Made in both Reflex and Transparent Glass in any of nine standard lengths, the gauge becomes an integral part of the vessel because it is welded directly to the outer wall.

Product Features

Standard covers are 3⅛” wide and a radius configuration is available for rounded tanks.

Welding pad gauges to be used on vessels less than 36” in diameter must be special ordered. The welding pad body must be machined to allow proper fit up. When ordering, add WP to gauge size number.

The chamber can be ordered in either carbon steel or stainless steel, and comes with a non-asbestos fiber gasket. Rust-proof carbon steel bolts are used in the construction of Glass-Trac Welding Pad Gauges.

Standard tempered borosilicate glass is rated up to 600°F. HP Borosilicate glass rated up to 600°F and aluminosilicate glass rated up to 800°F are also available.

Easy Installation of Glass-Trac Welding Pads

Questtec Solutions offers easy-to-follow installation instructions for our products. To assemble and install Glass-Trac Welding Pads:

- Assemble complete gauge with spacer plate (available on request) in place of gauge glass.

- Place gauge in exact location desired on empty vessel and weld around circumference of the pad.

- Allow the gauge to cool, then remove cover and spacer. Drill or burn top and bottom holes in vessel wall at the top and bottom of each gauge slot. Slot is 5/8″ wide.

- Replace gauge glass, gasket, cushion, and cover. Torque bolts to prescribed foot/pounds.

Note: While the gauge itself can be designed to withstand certain pressures, Glass-Trac cannot control the installation of each gauge or the load applied to the gauge by the vessel. Because of this, Glass-Trac cannot rate Weld Pad Gauges.

About Questtec Solutions

Questtec Solutions is an international company with representatives based around the world. Our Partners can assist with commissioning start up and calibration, 24-hour service, and repair support.

Questtec Solutions employs over 125 years of collective experience with all aspects of liquid level gauge and valve product lines. With a new state-of-the-art manufacturing facility and custom weld shop based in Houston, Texas, Questtec Solutions is able to provide innovative engineered solutions to meet our customer’s specific needs.