Glass-Trac Sightglass

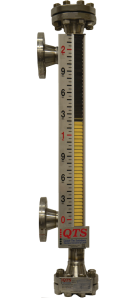

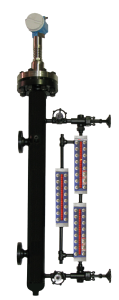

Glass-Trac Gauges, formally Daniel Level Gauge & Valve, are available in three main types:

- Reflex

- Transparent

- Tubular

These direct reading instruments are available in many different materials to meet your specific process conditions.

Following are some frequently asked questions our channel partners receive. If you have more questions, please feel free to contact us.

Frequently Asked Questions

Q: I’m not able to view the gauge glass. It appears it has been painted.

A: Under the yellow caution tape, there is a perforated cushion. This part protects the glass from dirt, dust, and debris until the gauge is ready to be placed in service. Pry up one edge and remove the perforated insert to expose the glass.

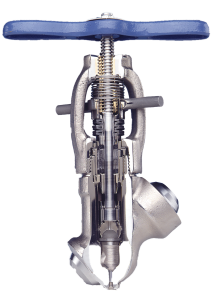

Q: My valve unions are leaking.

A: The unions are a ground metal joint. Increase the torque to the specified MSS-SP-25 specification to suggested 120’ lbs of torque on the ¾” 3000# union. Use a recommended long 36” pipe wrench. If union continues to leak, consult the factory.

Q: Do I need to re-torque the sightglass before putting into service?

A: Yes, all gauges are shipped with a torque tag. Follow the torque procedure listed on the torque tag.

Q: My process liquid is clear and tough to view using a transparent type gauge.

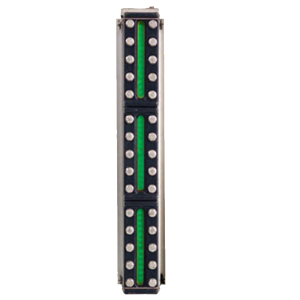

A: Questtec Solutions suggests using a See-Level LED Illuminator to add illumination to the back of gauge to increase level viewing.

Q: I need a spare glass lens and gasket for my level gauge.

A: Please refer to Page 24 of the Glass-Trac Catalog which provides kits and glass for gauges.

About Questtec Solutions

Questtec Solutions is an international company with representatives based around the world. Our Partners can assist with commissioning start up and calibration, 24-hour service, and repair support.

Questtec Solutions employs over 125 years of collective experience with all aspects of liquid level gauge and valve product lines. With a new state-of-the-art manufacturing facility and custom weld shop based in Houston, Texas, Questtec Solutions is able to provide innovative engineered solutions to meet our customer’s specific needs.