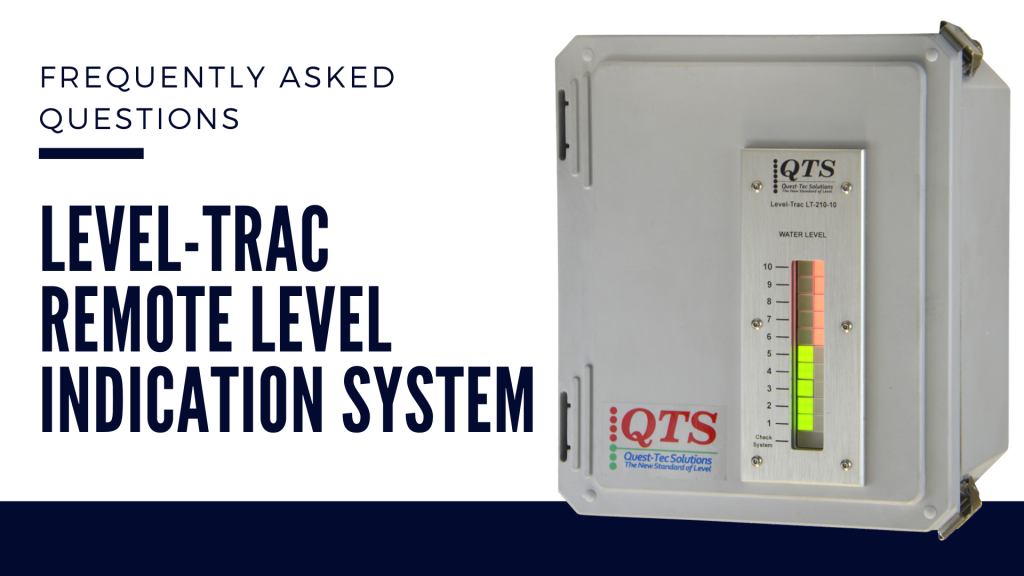

Level-Trac Remote Level Indication System

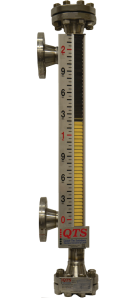

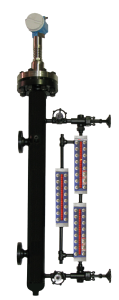

The Level-Trac water level indication product line is designed to satisfy the requirements of ASME Section I for “Independent Remote Water Level Indicators.”

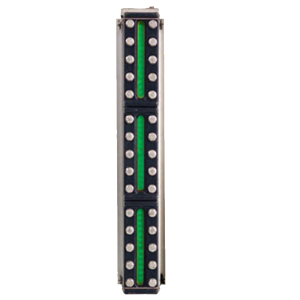

Built to last, Level-Trac manifolds feature robust construction to perform in the rigorous environment adjacent to steam generation equipment.

Level-Trac Control units are custom-configured at the factory to user requirements. Remote displays are designed to be mounted on a panel, utilize serial communication to reduce the wiring requirements, and offer flexibility in transmission from hard-wired with power from the Control Unit to fiber optic cable with local power.

Following are some frequently asked questions our channel partners receive. If you have more questions, please feel free to contact us.

Q: My unit is showing a checker board. What do I do?

A: Press the test buttons. This condition can be simulated by unplugging one of the probe plugs. If the test buttons perform as intended, it is the wiring. If the test buttons do not work, replace the Discriminator PCB.

Q: Why are there two wires for some probes?

A: The normally dry channels have a secondary continuity circuit between the two wires, which meet at the probe. This is to induce an out-of-sequence system fault.

To illustrate, first loosen a wire on a wet probe, and it will show dry, instead of wet. The fault system will engage. All is good.

Without the continuity circuit, a dry channel would respond the same way. But since the channel is expected to be dry, there would be no fault.

A break in the continuity will cause the channel to show wet, which will induce the fault.

Q: What is the blinking red light on the relay power supply PCB?

A: That indicates that there is communication status of the RS485 signal between the Control Unit and the remote display.

Blinking once per second indicates all good. If the Red LED on the Relay/Power Supply PCB is blinking every 5 seconds, it means that there is no transmission of signal.

About Questtec Solutions

Questtec Solutions is an international company with representatives based around the world. Our Partners can assist with commissioning start up and calibration, 24-hour service, and repair support.

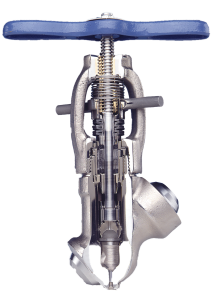

Questtec Solutions employs over 125 years of collective experience with all aspects of liquid level gauge and valve product lines. With a new state-of-the-art manufacturing facility and custom weld shop based in Houston, Texas, Questtec Solutions is able to provide innovative engineered solutions to meet our customer’s specific needs.